The unibody frame repair industry is undergoing a significant transformation due to advancements in automotive technology and the need for precision, efficiency, and consistent quality. Traditional on-the-job training is being replaced by structured, standardized programs encompassing technical skills, safety protocols, and modern digital tools like laser measuring systems and CAD software. This shift is particularly notable in complex repairs like bumper restoration as vehicles become increasingly sophisticated. Comprehensive certification programs now include specialized knowledge in metalworking techniques and high-tech equipment use, ensuring professionals can effectively handle modern vehicle repairs and enhance customer satisfaction. The future of unibody frame repair education will focus on digital technologies, advanced damage assessment, structural integrity analysis, and versatile technician training to meet the evolving market's demands.

The landscape of automotive repair is undergoing a significant transformation, particularly in the realm of unibody frame repair. As vehicle designs become increasingly complex, so do the training standards for technicians. This article explores the evolving training standards in unibody frame repair, highlighting key components and innovations that are shaping the future of this critical skill. We delve into current trends and make predictions about what’s next, providing valuable insights for both professionals and enthusiasts alike.

- Unibody Frame Repair: The Changing Landscape of Training Standards

- Key Components and Innovations in Modern Unibody Frame Repair Training

- Embracing the Future: Trends and Expectations in Unibody Frame Repair Education

Unibody Frame Repair: The Changing Landscape of Training Standards

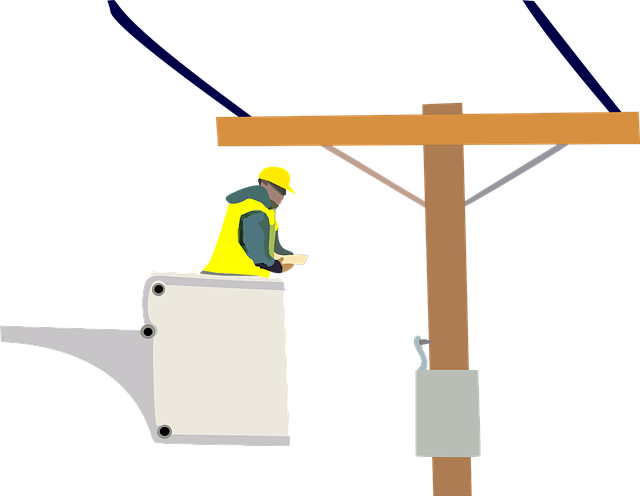

The landscape of training standards in unibody frame repair is undergoing a significant evolution, driven by advancements in automotive technology and the ever-increasing demand for precision and efficiency in collision repair shops. Traditionally, learning unbody frame repair involved on-the-job training and apprenticeships, but modern methods are integrating more structured, standardized programs to ensure consistent quality across the industry. These new standards focus not only on technical skills but also on safety protocols and the latest digital tools used in car bodywork repairs, such as laser measuring systems and computer-aided design software.

The shift towards standardized training is particularly notable for bumper repair and other complex car bodywork tasks. As vehicles become more sophisticated with advanced materials and designs, technicians need specialized knowledge to handle intricate repairs accurately. Therefore, certification programs are now more comprehensive, covering topics like metalworking techniques, structural integrity assessment, and the use of high-tech equipment in collision repair shops. This evolution ensures that professionals are equipped to handle modern vehicle repairs effectively, ultimately enhancing customer satisfaction through superior unbody frame repair services.

Key Components and Innovations in Modern Unibody Frame Repair Training

In the dynamic realm of automotive repair, Unibody Frame Repair Training is undergoing a significant evolution, driven by advancements in vehicle design and customer expectations. Modern unibody frame repair training programs are integrating key components that go beyond traditional techniques. These include state-of-the-art equipment, digital measurement tools, and advanced simulation software to ensure precise and efficient repairs. The curriculum now focuses on comprehensive learning, covering not just technical skills but also safety protocols, environmental considerations, and industry standards, reflecting the multifaceted nature of contemporary auto collision centers.

Innovations in training methods are mirroring the transformation within automotive body shops. Interactive workshops, virtual reality simulations, and hands-on practices using real vehicle parts are becoming staples. These approaches cater to a diverse range of learners, from novice technicians to seasoned professionals, ensuring they stay abreast of industry trends. With a strong emphasis on quality and accuracy, modern unibody frame repair training is poised to elevate the standards of auto body restoration, ultimately enhancing customer satisfaction in automotive service facilities.

Embracing the Future: Trends and Expectations in Unibody Frame Repair Education

The future of unibody frame repair education is poised for significant evolution, driven by advancements in technology and changing industry standards. As vehicles become increasingly complex with lightweight materials and sophisticated design features, training programs must adapt to meet these new challenges. Students enrolled in unbody frame repair courses can expect a focus on digital technologies, such as computer-aided design (CAD) software and 3D printing, which enable precise measurements, efficient repairs, and even the creation of custom parts. This shift towards digitalization not only streamlines the repair process but also enhances accuracy and reduces waste.

Furthermore, there is an increasing emphasis on comprehensive training that goes beyond basic repair techniques. This includes skills in damage assessment, structural integrity analysis, and learning about advanced materials used in modern car construction. As auto repair shops integrate tire services and car bodywork services alongside unibody frame repairs, technicians are expected to become well-rounded experts capable of handling a wide range of vehicle maintenance tasks. Such developments ensure that students are equipped with the knowledge and skills to thrive in an evolving market, where demand for skilled professionals continues to rise.