Electric vehicles' (EVs) unique unibody frames require specialized repair due to their complex structure and advanced materials. After an accident or damage, skilled technicians use diagnostic tools, CAD modeling, and precision techniques like laser cutting and robotic welding for meticulous repairs. Rigorous testing, adherence to industry standards, and quality control ensure EV safety and structural integrity while preserving their distinctive aesthetics and performance. Choosing reputable auto collision centers specializing in unibody frame repair offers peace of mind, guaranteeing top-notch craftsmanship and safety for EV owners.

Electric vehicles (EVs) are revolutionizing transportation, but their unique unibody frame construction presents specific challenges during repairs. This article delves into the intricacies of unibody frame damage in EVs and highlights critical repair requirements. From understanding the impact of common damage types to exploring specialized tools and techniques, each step ensures optimal restoration. Additionally, we emphasize the importance of quality control measures post-repair to maintain safety and performance, offering a comprehensive guide for professionals in this evolving industry.

- Understanding Unibody Frame Damage in Electric Vehicles

- The Specialized Tools and Techniques for Repair

- Ensuring Quality and Safety Post-Repair

Understanding Unibody Frame Damage in Electric Vehicles

Unibody frame damage in electric vehicles can arise from various incidents such as accidents, impact with debris, or even manufacturing defects. Unlike conventional cars with separate chassis and body components, electric vehicles (EVs) have a unified structure known as the unibody, which combines both the frame and body paneling. This design offers numerous benefits, including improved safety and reduced weight. However, when damage occurs to this integral component, it requires meticulous attention for effective repair.

Proper assessment is crucial to determine the extent of the damage. Technicians skilled in unibody frame repair use advanced diagnostic tools to inspect hidden areas, ensuring no structural compromise goes undetected. Repairs often involve intricate processes such as metal welding, panel replacement, and precise alignment to restore the EV’s original integrity. Given the precision needed, it’s essential to turn to professionals specializing in car restoration for top-notch unibody frame repair services, guaranteeing both safety and aesthetic excellence for these advanced vehicles.

The Specialized Tools and Techniques for Repair

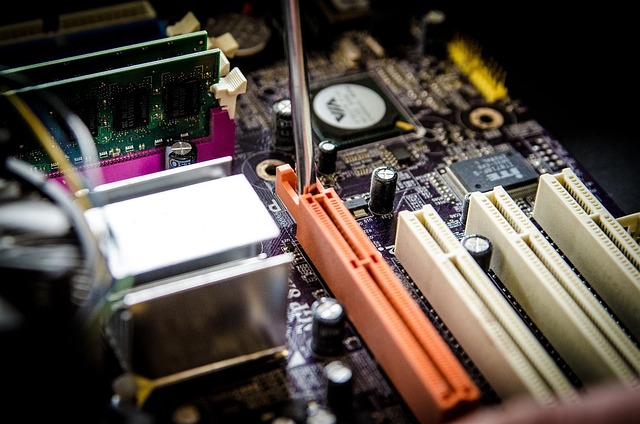

The world of electric vehicle (EV) maintenance requires a unique set of skills and specialized tools for unibody frame repair. Unlike conventional vehicles, EVs have complex, intricate structures that demand precision and expertise to fix. Technicians need advanced equipment like laser-guided cutting tools and robotic welding systems to ensure accurate, non-destructive repairs. These technologies enable precise manipulation of the lightweight materials commonly used in EV frames, such as aluminum alloys, while maintaining structural integrity.

The process involves careful disassembly, meticulous inspection, and expert reassembly. Collision repair services for EVs often incorporate advanced techniques like computer-aided design (CAD) modeling to create customized repair templates. This ensures that every component is aligned perfectly, preserving the vehicle’s original aesthetics and performance. Car paint repair and restoration play a significant role, too, as maintaining the EV’s sleek, modern finish is crucial to its overall appeal.

Ensuring Quality and Safety Post-Repair

After undergoing unibody frame repair, ensuring the quality and safety of the vehicle is paramount. This involves rigorous testing to verify structural integrity, alignment, and functionality. Advanced diagnostic tools and trained technicians are essential for accurate assessments. Reputable auto collision centers employ experienced professionals who adhere to strict industry standards, guaranteeing that every repair meets or exceeds safety requirements.

Proper repairs not only restore the vehicle’s structural soundness but also maintain its overall performance and longevity. A well-executed unibody frame repair should leave no room for compromise. Customers seeking car body repair services in auto body shops should demand evidence of quality control measures, certifications, and a track record of successful projects to ensure peace of mind on the road.

Unbody frame repair in electric vehicles requires a unique set of skills and tools due to their advanced design. By understanding the specific damage, employing specialized techniques, and prioritizing quality control, technicians can ensure these intricate vehicles return to peak performance. Effective unibody frame repair not only maintains structural integrity but also safeguards the safety and efficiency of electric vehicles on the road.