Unibody frame repair for premium vehicles like Mercedes-Benz is critical for structural integrity and safety after accidents. Accurate measurements using advanced technology are essential, ensuring comprehensive repairs that restore both cosmetic and structural elements, including safety systems. Meticulous precision in measurements sets professionals apart, avoiding misaligned panels and compromising vehicle strength or customer satisfaction. Best practices for accurate unibody frame repair include high-quality measuring tools, industry standards reference, proper training, distraction-free work environment, tool calibration, and detailed documentation.

In the realm of automotive craftsmanship, unibody frame repair stands as a delicate dance between precision and structural integrity. Accurate measurements are not merely desirable; they are the heartbeat of successful unibody frame repair. This article delves into the significance of precise measurements in restoring the structural backbone of vehicles, ensuring safety and longevity on the road. By exploring best practices and understanding the impact of accuracy, professionals can master this intricate art.

- Understanding Unibody Frame Repair: The Foundation of Structural Integrity

- The Impact of Accurate Measurements: Precision in Action

- Best Practices for Ensuring Accuracy During Unibody Frame Repair

Understanding Unibody Frame Repair: The Foundation of Structural Integrity

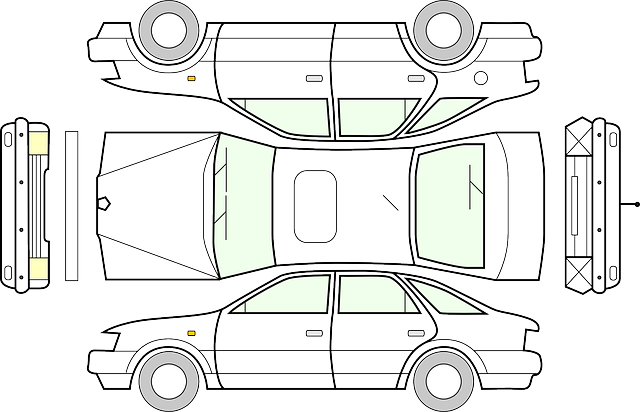

Unibody frame repair is a specialized process that forms the very foundation of structural integrity for modern vehicles, particularly premium brands like Mercedes-Benz. Unlike traditional separate body panels, unibody designs integrate the frame and body as one single unit, demanding meticulous precision during the repair process to maintain its original strength and safety standards.

When a vehicle experiences a fender bender or collision, accurate measurements become crucial. Every curve, angle, and joint must be precisely assessed to ensure that any repairs are not just cosmetical but structural as well. Reputable collision repair services understand this and employ advanced technology to measure and document the damage, allowing for a comprehensive unibody frame repair that reinstates the vehicle’s safety systems and driveshaft alignment, much like new.

The Impact of Accurate Measurements: Precision in Action

In the intricate world of unibody frame repair, accurate measurements are not merely a preference but an absolute necessity. Every millimeter counts when it comes to restoring a vehicle’s structural integrity. Precision measurements ensure that each component is aligned perfectly, allowing for seamless fusion of the repaired sections with the existing frame. This meticulous approach is what sets apart professional auto maintenance and automotive restoration experts from their peers.

When dealing with unibody frame repair, even the slightest error can have significant consequences. Inaccurate measurements may lead to misaligned panels, compromising the vehicle’s structural strength and aesthetics. However, when measurements are executed with meticulous care, it enables technicians to achieve flawless results, ensuring the safety and reliability of the repaired vehicle. This precision is vital in the auto maintenance industry, as it translates into higher quality repairs and satisfied customers.

Best Practices for Ensuring Accuracy During Unibody Frame Repair

To ensure accuracy during unibody frame repair, best practices involve a meticulous approach. This starts with using high-quality measuring tools such as laser measurements and precision calipers to capture exact dimensions. Technicians should also reference industry standards and manufacturing specifications for each vehicle make and model. Proper training on the latest repair techniques and equipment is crucial, ensuring every technician is proficient in their use.

Additionally, setting up a controlled work environment with minimal distractions helps maintain focus. Regular calibration of tools and equipment ensures consistent performance. Documentation plays a vital role too; detailed records of measurements, procedures, and adjustments ensure traceability and facilitate future reference during the vehicle paint repair or fleet repair services process.

In the realm of automotive repair, accurate measurements are the unsung heroes of unibody frame repair. They ensure structural integrity, precise alignment, and ultimately, the safety and reliability of vehicles. By adopting best practices and leveraging modern tools, professionals can deliver top-notch results, fostering customer trust and satisfaction in the process. Investing in accuracy is a game-changer for workshops aiming to excel in the competitive automotive industry, where precision and quality are paramount.